HOW IT WORKS

Plasma-Catalytic Technology Driving Methane Abatement

Innovating for a Methane-Free Future

How Plasma-Catalytic Technology Leads the way in Reducing Methane Emissions from Natural Gas and Dual-Fuel Engines

At the core of our R&D efforts is the development of cutting-edge technology aimed at solving one of the most pressing environmental challenges: methane emissions. SlipPure™ represents a breakthrough in methane abatement, utilising our proprietary plasma-catalytic process to reduce methane slip from natural gas and dual-fuel engines significantly. This technology, developed through extensive research, is a key innovation driving the global transition to cleaner energy.

Methane, a potent greenhouse gas, is responsible for 85 times more warming potential than carbon dioxide over a 20-year period. Our plasma-catalytic process helps reduce these emissions and positions industries to meet future regulatory demands while supporting sustainability efforts.

How the Plasma-Catalytic Process Works

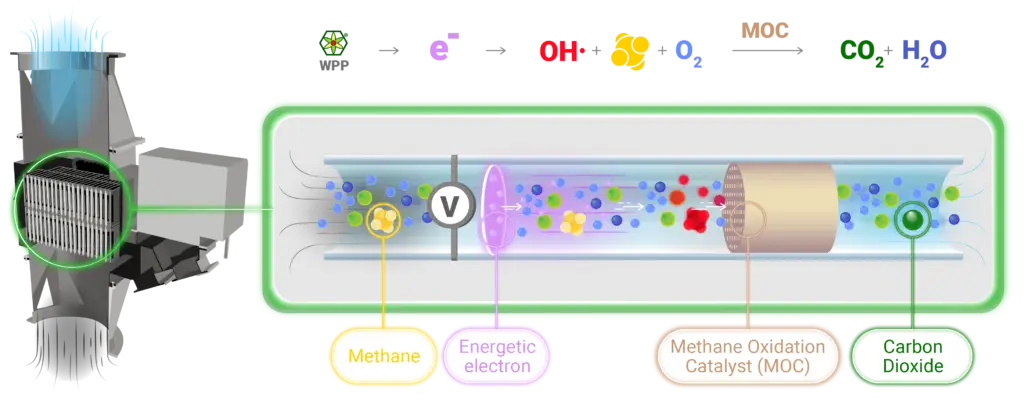

Our plasma-catalytic technology combines two powerful methods for methane abatement:

- Non-Thermal Plasma (NTP): NTP generates highly energised electrons interacting with methane molecules in the exhaust stream, activating them and reducing the activation energy required for methane oxidation. This makes the process highly energy-efficient.

- Methane Oxidation Catalyst (MOC): The methane oxidation catalyst then converts methane (CH4) into carbon dioxide (CO2) and water (H2O), ensuring that methane is effectively removed from the exhaust with minimal energy input.

This combination allows SlipPure™ to operate efficiently at lower exhaust temperatures, making it adaptable across various engine types. The technology improves methane abatement and ensures compliance with stringent environmental regulations.

Image: Illustration of the plasma-catalytic process behind our methane reduction technology.

Why Plasma-Catalytic Technology is Different

The development of our plasma-catalytic process represents a significant leap forward in emissions reduction technology. Methane slip has long been an unsolved challenge in industries reliant on natural gas and dual-fuel engines. Traditional methods often require high temperatures and large amounts of energy, whereas our technology delivers high efficiency with minimal energy consumption.

Energy Efficiency

Unlike conventional abatement systems, SlipPure™ relies on electrical power to generate non-thermal plasma, making it a more sustainable and cost-effective solution for methane reduction.

Scalability

This technology's versatility allows it to be applied to both land-based and marine engines, making it relevant for industries ranging from power generation to maritime transport.

Long-Term Compliance

SlipPure™ is designed to meet current and future emissions standards, ensuring that businesses stay compliant as regulations evolve.

The Bigger Picture

Methane emissions are a critical global challenge. Addressing them is key to achieving climate goals and improving air quality. Learn more about the broader impact of methane abatement and how it contributes to sustainability.

Case Study

Methane Abatement Success

Our R&D department’s recent trials demonstrated a 99% reduction in methane emissions using our SlipPure™ technology. This success is a testament to the effectiveness of our plasma-catalytic process, showcasing its potential to drive significant environmental impact across industries.